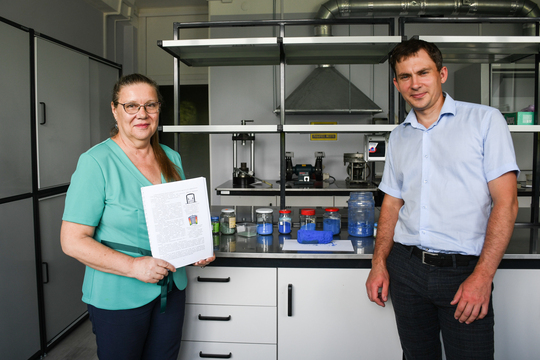

High-quality pigments in three popular colors developed at TSC SB RAS

Scientists at Tomsk Scientific Center SB RAS have developed a technology for producing fine inorganic pigments in three colors – blue, green, and khaki. The iron triad-based pigments produced via self-propagating high-temperature synthesis (SHS) are non-toxic and highly durable. The entire process takes minutes and does not require expensive equipment. The findings have been published in the first-quartile journal

Ceramics International

.

– One of the advantages of the new method is that we’ve managed to take the grinding out of the equation. Otherwise laborious process required to achieve the right size of the particles would take a while since spinel-type pigments are almost as hard as diamonds. To work this around we obtain particles of the desired size by using special gasifying additives that help prevent sintering and crystal growth, – explained Nina Radishevskaya, Senior Researcher at the Laboratory of Heterogeneous Metallic Systems at TSC SB RAS.

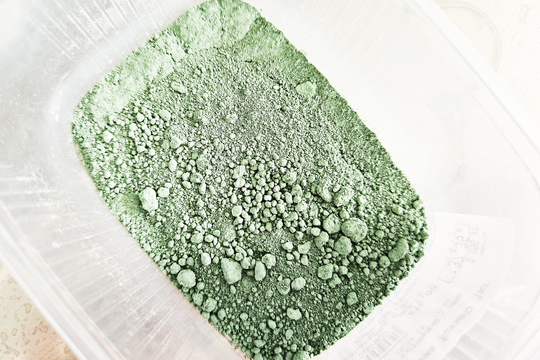

In a word, the pigment production process can be described as very hot and very fast! The synthesis occurs at temperatures within a range of 1200 to 1600 °C and lasts no more than a minute, with minimal electricity consumption. According to Oleg Lvov, Junior Researcher at the laboratory, the initial mixture (charge) is placed in a special container. The mixture includes aluminum, which acts as a fuel, along with oxides of cobalt, zinc, nickel, iron, or chromium, as well as a gasifying additive – aluminum hydroxide. The SHS process is driven by two parallel exothermic reactions: aluminum oxidation and the aluminothermic reaction. These reactions release heat, raising the temperature of the initial mixture to levels necessary for spinel synthesis.

As the initial mixture is heated, the structure of aluminum hydroxide rapidly breaks down, producing gaseous reaction products that prevent the spinels formed during synthesis from sintering. The active aluminum oxide, produced by thermal decomposition of aluminum hydroxide, reacts with the transition metal oxides, forming pigments with particle sizes of approximately 1-5 microns. The scientists studied the structure of these pigments using X-ray diffraction analysis and IR spectroscopy, while their microstructure was examined using optical and scanning electron microscopes.

Inorganic pigments are widely used in overglaze and underglaze colors for ceramic and porcelain products, in paints and coatings, in finishing and construction mixtures, in powder coatings for metals, and in colored fillers for polymers used in 3D printing. The pigments developed at TSC SB RAS exhibit high chemical, atmospheric, and thermal resistance. Their production technology is environmentally safe, energy-efficient, and geared towards local raw materials.